Checking Jigs – Modern production assembly relies on parts and assemblies from disparate manufacturing streams to fit precisely.

Modern automotive light units are complex assemblies of many individual components and have to fit exactly into the apertures provided in compound 3-dimensional shapes in the vehicle body. Ensuring their consistent manufacture to exacting tolerances is essential in today’s demanding market.

Specialist component manufacturer supplying premium automotive clients around the world, have traditionally used high cost, high precision CMM gauges for measuring a small number of components picked off the production line, but this can be too time-consuming and expensive to pinpoint components outside the required tolerances.

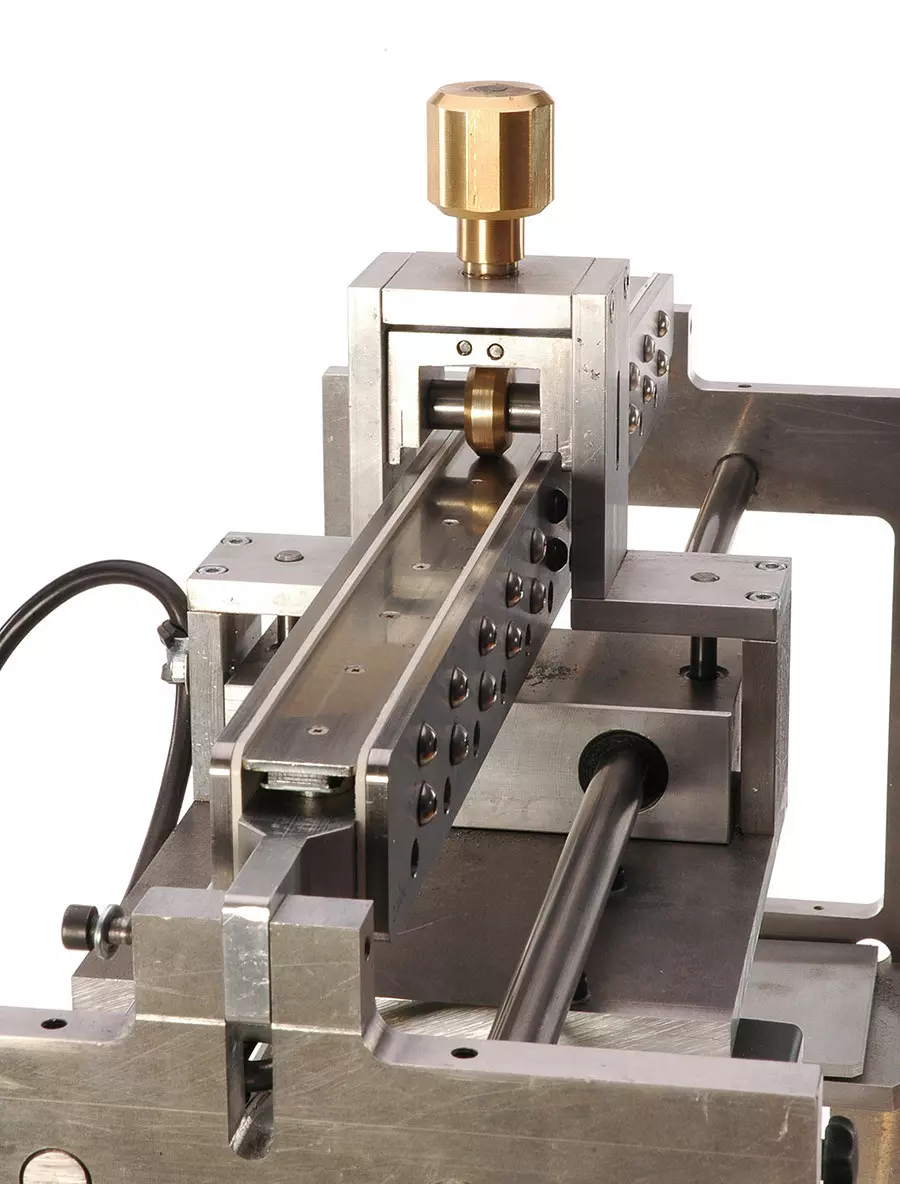

Rapitypes CNC machined “go/no go” gauges which are simple and quick to use both during production and at the end of the line are a cost effective and convenient solution to the problem. These gauges are easy to order and simple to implement in any production environment. Any distortion or deviation from size and shape is immediately visible, without having to resort to the highly-skilled digital evaluation of individual parts. This means that 100% Checking Jigs is possible without incurring a time and cost penalty.

The Rapitypes simplified gauges have been proven to reduce quality control failure rates to almost zero. They have significantly cut labour costs and have improved quality control throughout the production process – an improvement which can be replicated across many other sectors outside the automotive industry.