For clients with a limited manufacturing resource or indeed none at all, external product assembly provision is a vital thread in their business model, and one that should ideally be provided by the parts manufacturers. Of course modern products often require the manufacturer to deploy extensive, specialist build provision across a spectrum of mechanical, and electronic assembly, and this often means shipping sub-assemblies from one location to another in order to complete the build.

Product Assembly

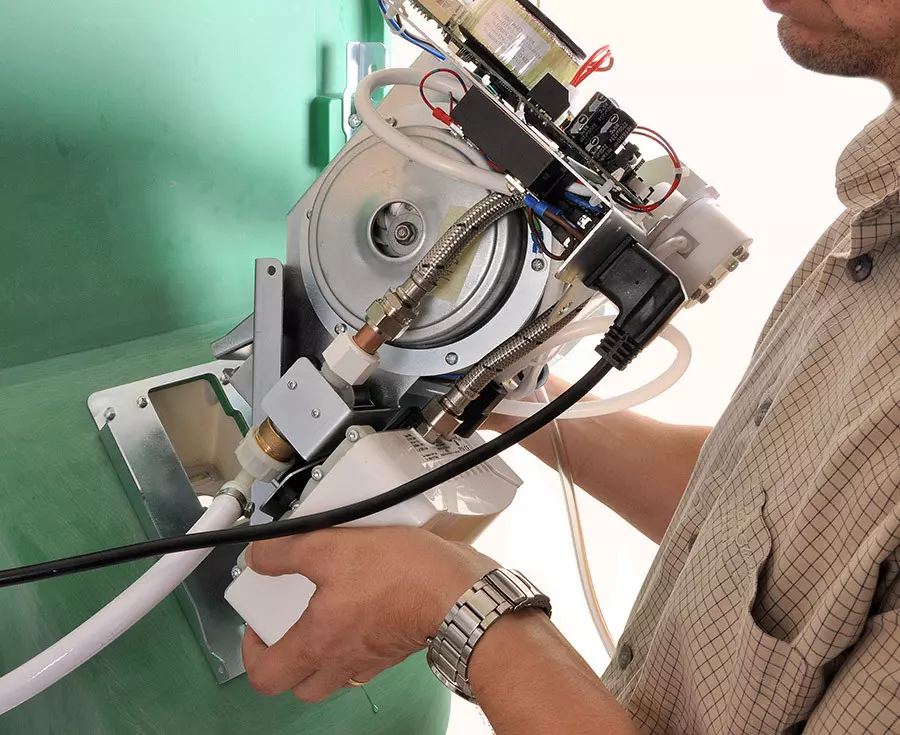

Rapitypes has amassed a wealth of product assembly capabilities for deployment on behalf of its clients. Capabilities that start with parts checking and quality control, and end with electronics assembly, testing and shipping. The company employs the latest CMM technologies to ensure the parts it produces are accurate and within the correct tolerance. It has extensive product assembly areas with provision for moulding machine-side assembly as well. And when electronics are incorporated into the products, the company can carry out 100% checking and soak testing prior to sign-off and shipping.

All these facilities are available for client inspection at any time, and in fact Rapitypes encourages its clients to visit and become involved in the process at all levels prior to, and during the build project.

Being our client’s virtual product manufacturing facility has proven to be very attractive to many as the provision can be brought on-stream when required, and in response to prevailing orders, but it is also very attractive in terms of inventory as we are also able to store component parts on behalf of our clients thus shortening still further the response time to demand.

Please contact us for details of this service and a full list of available task fulfilments.