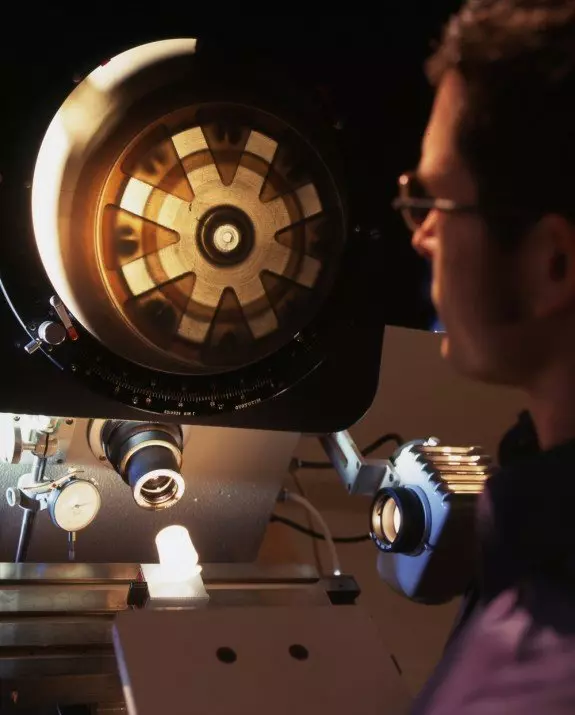

PROTOTYPE TESTING

Non-destructive testing (NDT) is a wide group of analysis techniques used in science and industry to evaluate the properties of a material or the components of a system without causing damage. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both time and money in product evaluation, troubleshooting, and research.

Rapitypes can apply the following tests: – ultrasonic crack detection, liquid penetration, radiographic and eddy-current testing.

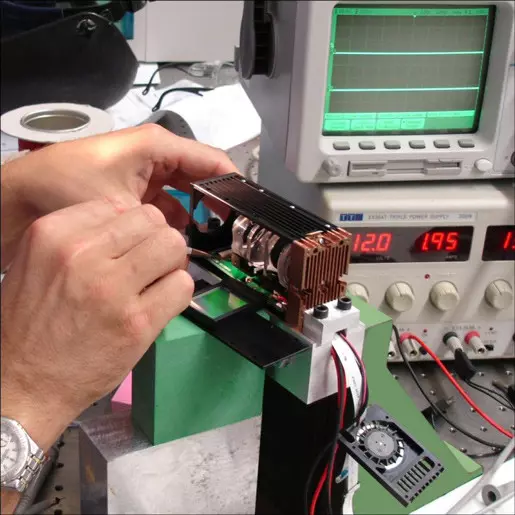

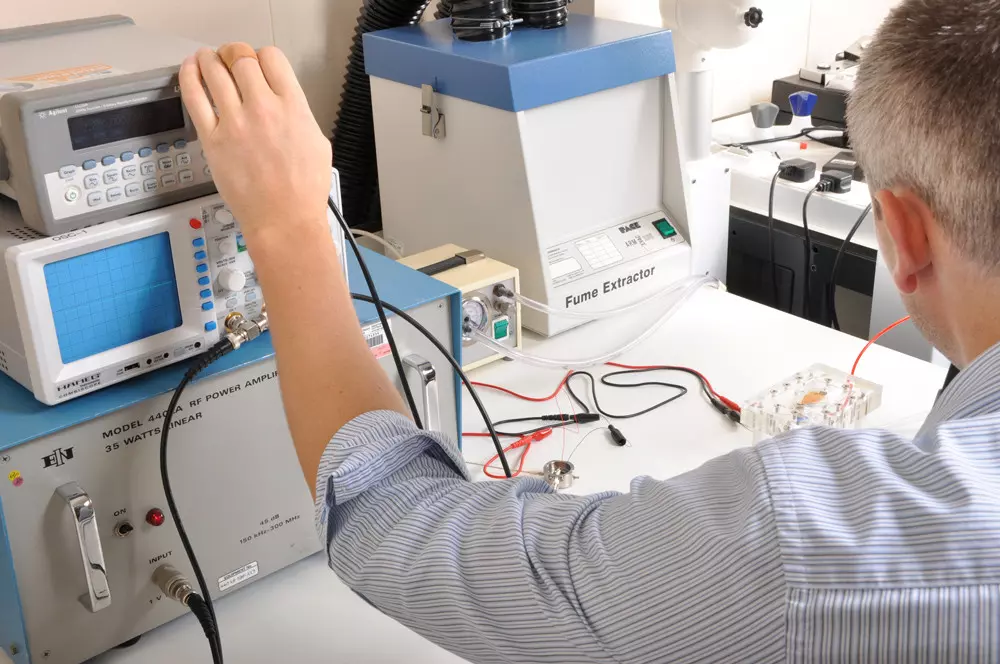

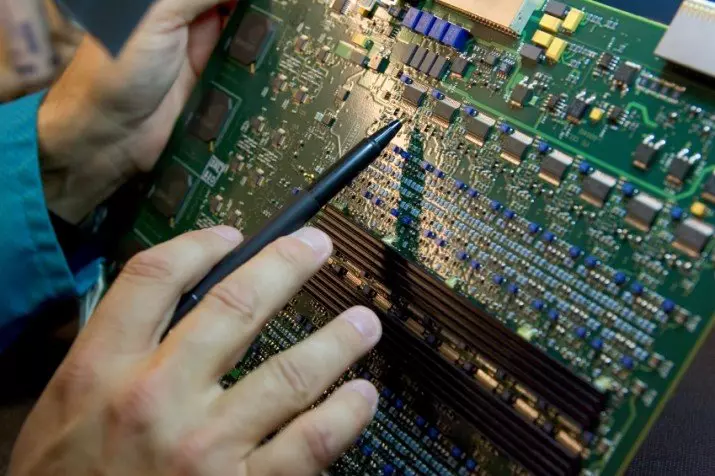

ELECTRONICS TESTING

Rapitypes can deploy electronic test equipment (to create signals and capture responses from electronic Devices Under Test – DUTs). These tests ensure the proper operation of the DUT and highlight faults at an early stage in the development. Use of electronic test equipment is essential to any serious work on electronics systems. Practical electronics engineering and assembly requires the use of many different kinds of electronic test equipment including fully automatic, bespoke systems.

SOAK TESTING

Soak testing involves testing a system with a given load extended over a significant period of time, to discover how the system behaves under sustained use. For example, in software testing, a system may behave exactly as expected when tested for 1 hour. However, when it is tested for 3 hours, problems such as memory leaks cause the system to fail or behave randomly. Rapitypes has secure areas dedicated to this activity on site.