RAPITYPES SPECIALISE IN THE PROTOTYPING AND LOW-VOLUME MANUFACTURE OF PLASTIC COMPONENTS.

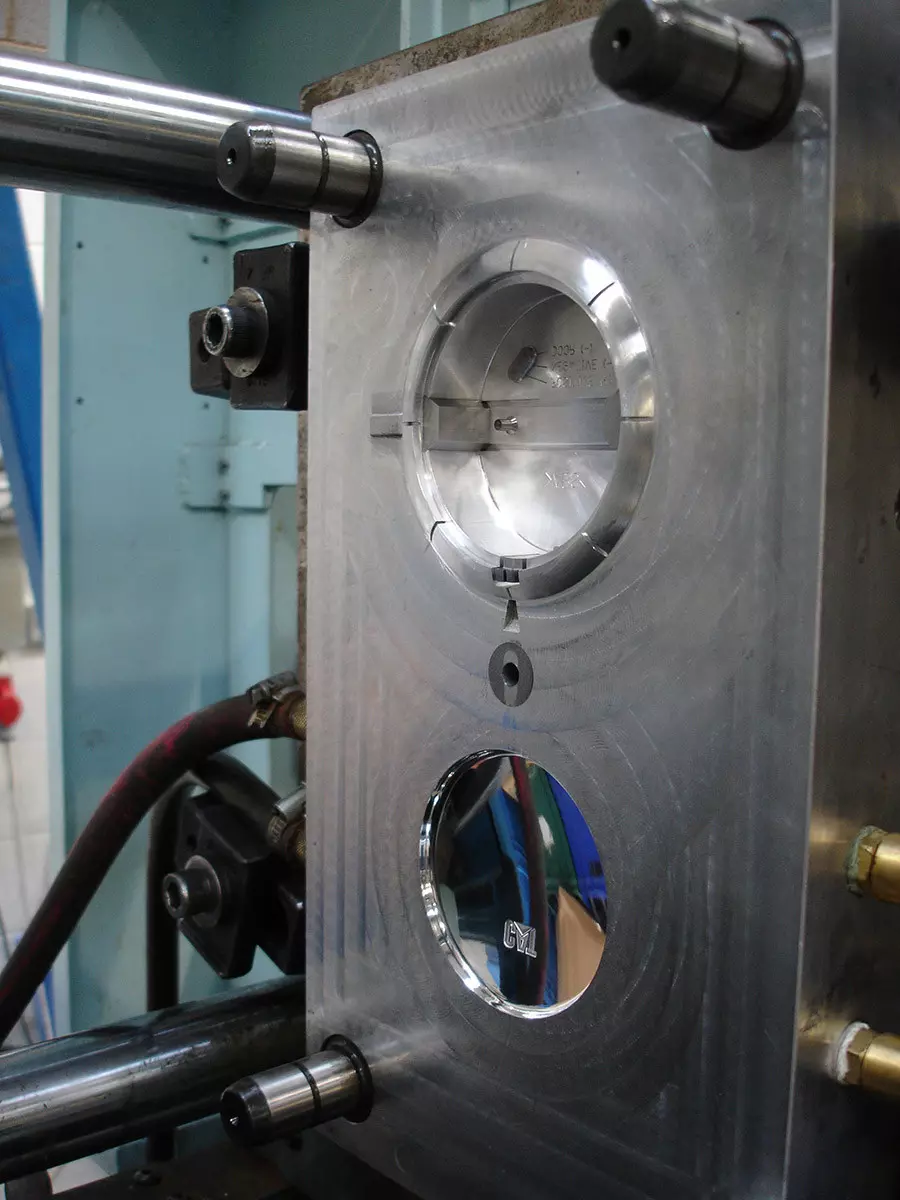

Most clients appreciate a company that can take the strain – a willing organisation with skills at hand and advice to offer. So when production intent rapid tooling components are needed to fast track a pilot build, or perfect a drop test, or conduct a consumer trial, or run an analysis or carryout environmental testing, Rapitypes can step in with the answer.

Their help can make the task of getting prototype parts or low-volume production components in target plastic materials straight forward and cost effective. Using the latest 3 & 5 axis high speed CNC machining centres, Rapitypes can produce highly accurate components in the selected target thermo plastic material, direct from CAD data.

High speed CNC machining can also be a solution for low-volume production requirements – if the predicted volumes do not warrant an investment in injection mould tooling, this option can be an attractive alternative.

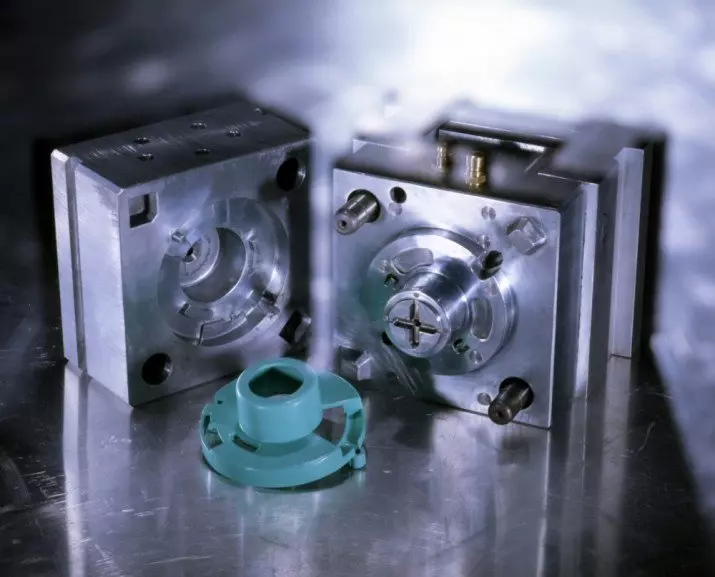

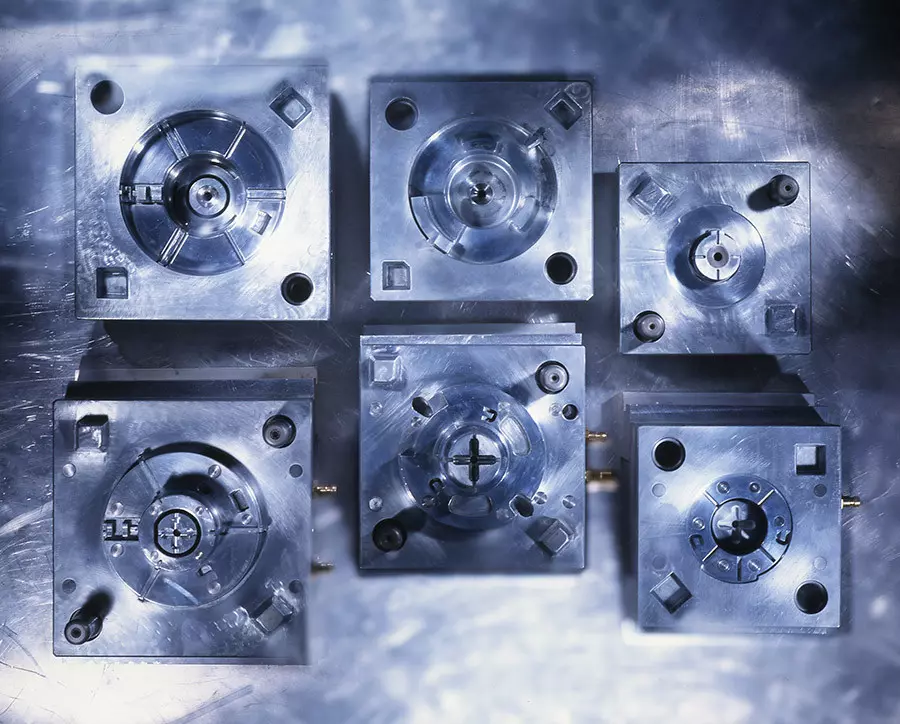

Rapid Tooling

All of our customer facing staff are fully trained or have many years of experience in the plastic manufacturing environment, so good advice is always at hand as well. We can advise on the choice of materials, and the impact of a specific design on the manufacturing process – we can even propose best practise design detailing to minimise production and material costs.

Rapitypes has offered these services for more than 30 years, and brought a unique support mechanism to the medical, scientific, automotive and consumer product sectors. Precision pre-production plastic prototype and low volume production parts are our focus, and with the machining facility, QA and design support facilities under one roof, we can confidently say that we have the means to give our clients that all important business edge.