So these days it’s all too easy to assume that a 3D print or rapid prototype is all that’s required to achieve a working prototype – Attach a few pieces together, add the working parts and Hey Presto, job done. Well, as most who are involved in product development will already know, it’s not quite as straightforward as that. The 3D print is just the feedstock for what is largely a bench activity where engineers and model makers use their skill and dexterity to create the working prototype.

Working Prototype

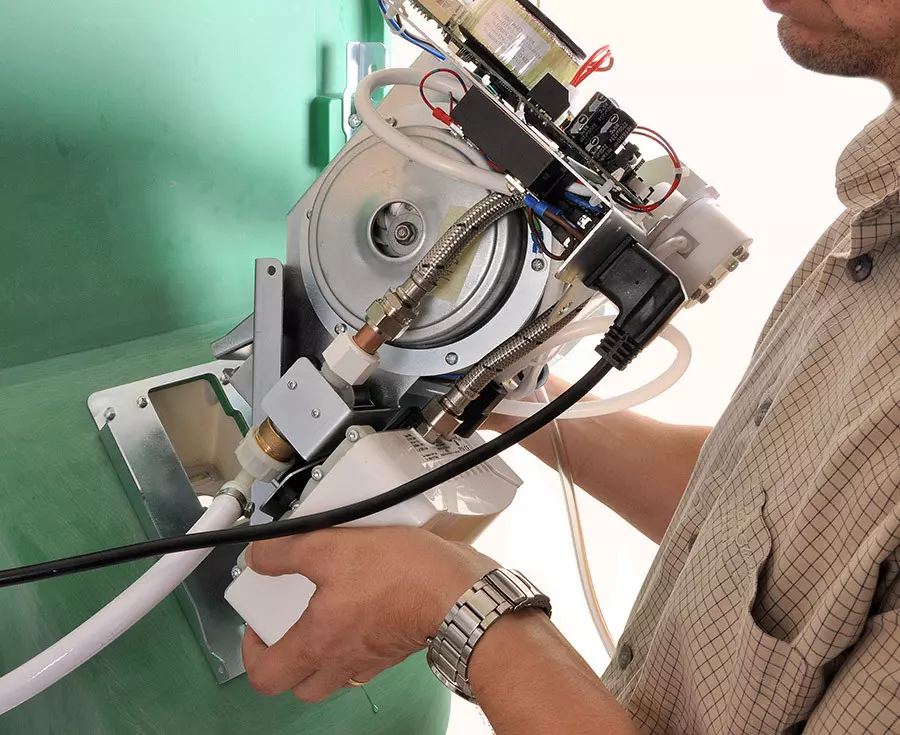

A typical product prototype will incorporate electronics, sensors, motors, and some form of GUI. It will need to be capable of withstanding a reasonable level of loading and impact force as it goes through limited testing and assessment, and it will also be scrutinised by manufacturing engineers who will use it to assess the best method of producing and assembling the component parts. And finally the working prototype could be subject to the visual assessment of marketeers and potential users. All in all, the working prototype represents a significant milestone in the development of a new product and its impact can be pivotal in the success of the enterprise.

Rapitypes has been providing working models and prototypes to clients in all industry sectors for more than 25 years. During this time we’ve built a team with the capability to deliver robust models of all types and at virtually any scale.

We use 3D printing, CNC machining, fabrication, and a host of other machine and hand processes to build each working prototypes. We can provide all the capability to produce electronic circuits, create the firmware and populate PCBs. We can provide assistance with setting up GUIs, sensors, input/output, as well as handling all the electrical and mechanical aspects of a working prototype form first concepts to finished unit. We also have the facilities to carry out limited mechanical and electronic testing on behalf of our clients.

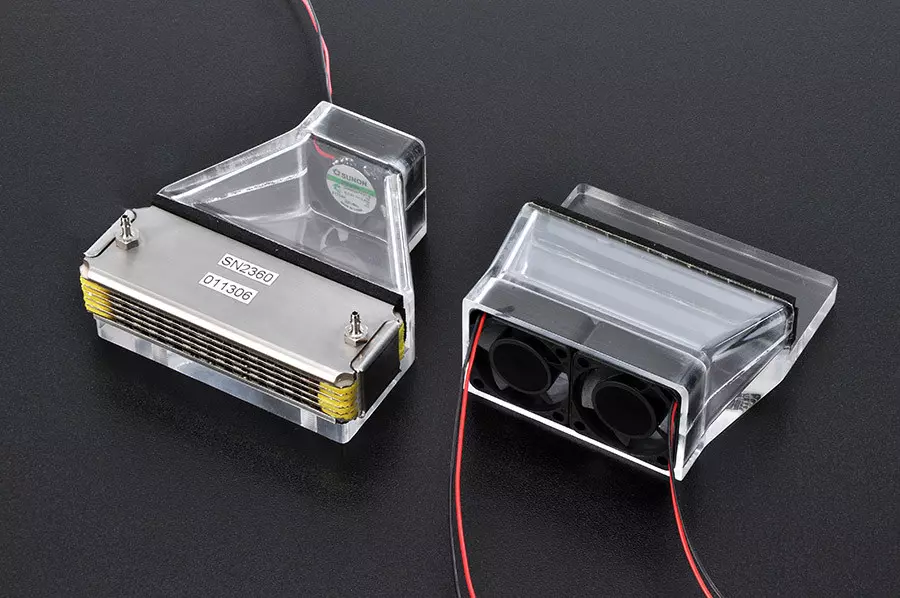

In addition to the electronic and electro-mechanical, we also offer assistance with working prototypes for the bioscience sector. Our toolmaking facilities and small scale injection moulding machines allow us to provide multiple prototypes of small vessels and conduits, reaction bowls, fluid circuits, probes, closures and general mechanisms. We have a laboratory in which the working prototypes can be previewed during the development and our systems are compliant with ISO 13485.