Rapitypes, one of the UK’s leading manufacturers of technical polyurethane RIM production components for the automotive and medical sectors, has experienced a significant growth in business for 2010/11.

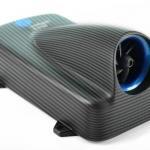

The increase has led to a substantial investment in new dispensing systems, like the Cannon B15 illustrated and the expansion of the RIM facility from 15,000 sq ft to 20,000 sq ft. This includes a larger warehouse facility for customer stock components (JIT) and extended trimming, shot blasting and clean room spray-paint finishing areas.

With 12 years experience in RIM production, Rapitypes continue to satisfy their customers by focusing on the unique requirements of the project and the highest levels of quality. This is exemplified by an impressive portfolio of clients including Adventa Healthcare, Aston Martin, Bentley Motorcars, Rolls Royce Motorcars and Triumph Motorcycles.

A continuous programme of improvement and innovation has allowed Rapitypes’ customers to enjoy the benefits of hollow components through ‘Roto RIM’, electrically conductive coatings, UV stable and colour matched substrates, and in-mould coated surface finishes, which are harder wearing and more economical to apply than by spray painting.

RIM is perfect for larger components in lower volumes. Rapitypes can supply parts in shot weights of up to 15Kilos.